|

Sumitomo SH 280 ton

Sumitomo SH 280 ton Specification

- Weight

- Approx. 19,000 kg

- Output

- Variable, up to 700 shots per hour

- Feature

- High Precision, Energy Saving

- Used For

- Plastic Product Manufacturing

- Manufacturing Year

- 2015

- Machine Type

- Injection Moulding Machine

- Condition

- Used

- Capacity

- 280 Ton Clamping Force

- Origin

- Japan

- Dimension (L*W*H)

- 7.6 x 2.1 x 2.2 m

About Sumitomo SH 280 ton

Sumitomo SH 280 ton

We are largest suppliers in india Somitomo 280 ton 96 (injection moulding machine). the Somitomo in good condition to manufacturer the product. we provide the machine Somitomo in working condition

We provide the range of fully automatic plastic injection moulding machines to our customers. We offer these products in global market within definite time and at affordable prices, with following specifications:

|

Make |

|

MITSUBISHI |

|

Model |

|

350MGII-40 |

|

Making Year |

|

1990 |

|

clamping force |

Ton |

350 |

|

screw diameter |

mm |

62 |

|

shot weight PS |

g |

1030 |

|

shot volume |

cm |

1120 |

|

injection pressure |

kgf/1/2 |

1640 |

|

tie bar distance H x V |

mm |

730 x 730 |

|

mould height min |

mm |

300 |

|

mould opening stroke |

mm |

950 |

|

Total Opening ( Daylight) |

mm |

1250 |

|

Ejector stroke |

mm |

125 |

|

Ejector Force |

Ton |

8.3 |

|

main motor |

Kw |

45 |

|

heating total Load |

Kw |

15.6 |

|

machine weight |

Ton |

14.4 |

|

dimensions of the machine L x W x H |

m |

7.95 x 1.84 x 1.92 |

|

Oil Tank |

|

900 |

Precision Engineering and Productivity

Capable of delivering up to 700 shots per hour with a high injection weight and fully automated PLC, the Sumitomo SH 280 is engineered for productivity and precision. Its clamp force of 280 tons and adjustable moulding capacities make it particularly responsive to diverse plastic product manufacturing requirements.

Efficient Operation with Advanced Features

Energy-saving systems and robust motor power (37 kW) are at the heart of this Japanese-made machine. With a noise level 75 dB(A) and a rapid 2.3-second dry cycle, it balances performance with a comfortable working environment. The machines high-capacity tanks and large hopper support continuous, efficient production cycles.

FAQs of Sumitomo SH 280 ton:

Q: How does the PLC-based control system benefit the injection moulding process?

A: The fully automatic PLC (Programmable Logic Controller) system enhances accuracy and repeatability during moulding. It simplifies settings adjustment, provides consistent monitoring, and supports automation, leading to improved product quality and faster cycle times.Q: What types of plastic products can be manufactured using the Sumitomo SH 280 ton machine?

A: With a maximum injection weight of 992 g (PS), a 70 mm screw diameter, and adjustable mould height, this machine is suitable for producing a wide range of medium to large plastic items, such as automotive parts, containers, and industrial components.Q: When is the optimal time to use this injection moulding machine during production?

A: The Sumitomo SH 280 is ideal for high-volume, continuous plastic product runs, especially when consistency and precision are crucial. Its rapid cycle time and high output rate make it suitable for fast-paced manufacturing environments.Q: Where is the Sumitomo SH 280 manufactured and who is it best suited for?

A: This machine originates from Japan and is distributed, exported, and supplied throughout India. It serves manufacturers, distributors, exporters, and importers who need reliable used equipment for plastic manufacturing.Q: What is the process for maintaining the Sumitomo SH 280 to ensure optimal performance?

A: Routine maintenance involves monitoring the oil tank (430 L), ensuring the cooling water supply (1200 L/hr), cleaning the hopper (50 L capacity), and regular inspection of moving components. Following manufacturer guidelines ensures longevity and reliable operation.Q: How does this machine contribute to energy savings?

A: Its efficient motor system and PLC-controlled automation minimize waste and optimize power usage. This results in lower operational costs and aligns with modern energy-saving standards in manufacturing.Q: What are the main benefits of using a used Sumitomo SH 280 ton injection moulding machine?

A: Purchasing a used model provides cost efficiency while delivering high precision, robust performance, and advanced features typically found in newer equipment. Its reliability, large output capacity, and established brand reputation make it a valuable investment for growing businesses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Used Plastic Injection Moulding Machinery Category

Used Plastic Injection Molding Machinery

Color : Green

Used For : Manufacturing plastic products and components

Capacity : 220 tons clamping force

Feature : High Efficiency, Durable Structure, Energy Saving

Output : 350 shots per hour

Condition : Used

JSW 450 ton

Color : Blue & White

Used For : Plastic Product Manufacturing

Capacity : 450 Ton Clamping Force

Feature : High Precision, Energy Saving, Automatic Operation

Output : High Output Rate

Condition : Used

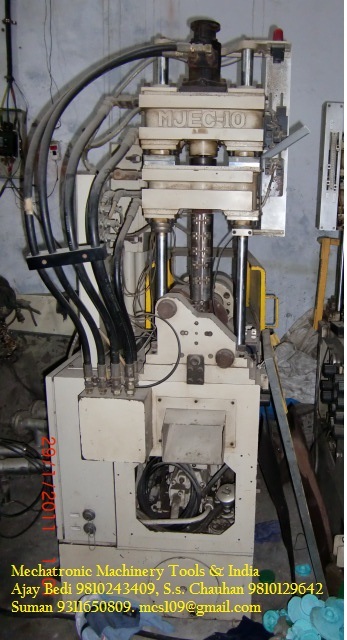

M Jec 10 ton make:-1997 L Type

Color : Sky Blue

Used For : Heavy material forming, bending, punching, straightening

Capacity : 10 Ton

Feature : Sturdy construction, manual and automatic modes

Output : Precision forming and bending tasks

Condition : Used

Nissei 40 ton

Color : White and Blue

Used For : Plastic Product Manufacturing

Capacity : 40 Ton Clamping Force

Output : Up to 70 cycles/hour

Condition : Used

|

MECHATRONICS MACHINERY & TOOLS (INDIA)

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry