|

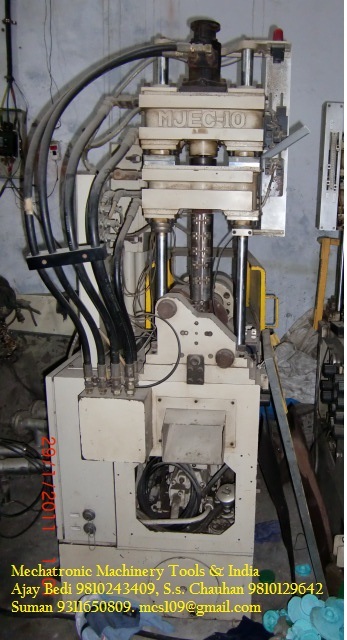

M Jec 10 ton make:-1997 L Type

M Jec 10 ton make:-1997 L Type Specification

- Condition

- Used

- Capacity

- 10 Ton

- Output

- Precision forming and bending tasks

- Color

- Sky Blue

- Dimension (L*W*H)

- 4000mm x 2000mm x 3000mm

- Weight

- Approx. 8500 kg

- Manufacturing Year

- 1997

- Machine Type

- L Type Hydraulic Press

- Voltage

- 415 V

- Feature

- Sturdy construction, manual and automatic modes

- Used For

- Heavy material forming, bending, punching, straightening

- Origin

- India

About M Jec 10 ton make:-1997 L Type

Vertical Plastic Injection Moulding Machines

We present a wide array of vertical plastic injection molding machines, which are in high demand in the markets. Specially designed, these vertical plastic injection molding machines are also equipped with electrical & hydraulic safety interlocks.

We also provide customized plastic injection molding machines as per clients specifications.

We provide the range of fully automatic plastic injection moulding machines to our customers. We offer these products in global market within definite time and at affordable prices, with following specifications:

|

Make |

|

M - Jec L Type |

|

Model |

|

10 ton |

|

Making Year |

|

1997 |

Engineered for Heavy Material Forming

This L Type Hydraulic Press is ideal for tasks that require robust force and precision. Its 10-ton capacity provides ample power for bending, punching, and straightening a variety of heavy materials. Designed for professional use, it suits large-scale manufacturing and fabrication environments.

Advanced Safety and Efficient Lubrication

Operator safety is prioritized with features like the emergency stop and pressure relief valve. Centralized automatic lubrication minimizes maintenance efforts while maximizing the longevity and smooth operation of the machine, making it reliable for prolonged use.

Precision and Productivity

With an approximate cycle time of 30 seconds and precision forming capabilities, the press supports high productivity without compromising on quality. Its reliable gear pump and spacious bed accommodate diverse workpieces, delivering consistent and accurate results in every cycle.

FAQs of M Jec 10 ton make:-1997 L Type:

Q: How is the M Jec 10 Ton L Type Hydraulic Press operated?

A: This machine can be operated in both manual and automatic modes, depending on the requirements of your production process. The controls are user-friendly, and transitions between modes are seamless, providing flexibility for various tasks.Q: What maintenance processes does the hydraulic press require?

A: The press features a centralized automatic lubrication system, which significantly reduces manual maintenance. Regular inspections are advised, especially for the oil tank (120 liters) and pressure relief systems, to ensure optimal and safe operation.Q: When is the hydraulic press most beneficial to use?

A: It is best utilized for heavy-duty industrial applications such as material forming, bending, punching, and straighteningespecially when precision and redundant safety are priorities. Its robust design ensures durability during continuous operation.Q: Where can this hydraulic press be installed?

A: The press is suitable for various industrial environments, including fabrication workshops, manufacturing plants, and metalworking facilities. Its sizable dimensions (4000mm x 2000mm x 3000mm) require adequate floor space and proper electrical provisions (415 V supply).Q: What are the safety features available on the machine?

A: For operator protection, the press is equipped with emergency stop buttons and a pressure relief valve. These features help prevent accidental injuries and safeguard the machine during unexpected events.Q: How does the hydraulic press contribute to production efficiency?

A: The machines quick cycle time of about 30 seconds and precise hydraulic control ensure faster task completion and consistent product quality, ultimately increasing throughput and reducing downtime in high-volume production settings.Q: What types of tasks or materials can this press handle?

A: Designed for heavy-duty operations, the press excels at forming, bending, punching, and straightening thick or dense materials commonly encountered in industrial manufacturing and fabrication sectors.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Used Plastic Injection Moulding Machinery Category

Cinncinati-600 1999

Machine Type : Hydraulic Press Brake

Origin : USA

Used For : Sheet Metal Bending

Condition : Used

Capacity : 600 Tons

Output : Multiple Bending Cycles/Minute

Sumitomo SG 100 ton make:-1999

Machine Type : Injection Molding Machine

Origin : Japan

Used For : Plastic Component Production

Condition : Used

Capacity : 100 Ton

Output : Max 240 shots per hour

JSW50TON Used Machinery

Machine Type : Injection Molding Machine

Origin : Japan

Used For : Plastic Product Manufacturing

Condition : Used

Capacity : 50 Ton Clamping Force

Output : High Precision Plastic Components

used Plastic Injection Molding Machinery

Machine Type : Plastic Injection Molding Machinery

Origin : Imported

Used For : Molding plastic components, industrial and commercial parts

Condition : Used

Capacity : 250 tons clamping force

Output : Up to 250 shots/hour depending on part size

|

MECHATRONICS MACHINERY & TOOLS (INDIA)

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry