|

JSW 50TON Injection Moulding Machine

JSW 50TON Injection Moulding Machine Specification

- Manufacturing Year

- 2016

- Output

- High Output/Hour (Depends on Product & Mould)

- Capacity

- 50 Ton Clamping Force

- Weight

- Approx. 3,500 kg

- Origin

- Japan

- Condition

- Used, Good Working Condition

- Dimension (L*W*H)

- Approx. 4.2 x 1.2 x 2.1 meters

- Machine Type

- Hydraulic Injection Moulding Machine

- Color

- White & Blue

- Voltage

- 380V, 3 Phase

- Feature

- High Precision, Energy Efficient, Easy Operation

- Used For

- Plastic Product Manufacturing

About JSW 50TON Injection Moulding Machine

Screw Type Plastic Injection Moulding Machine

Our clients can avail from us high performing Screw Type Plastic Injection Moulding Machine. These provide complete solutions for all kinds of hydraulic and pneumatic operations and rank best on reliability, quality and performance standards.

It is operated by a high torque motor that aids in efficient screw drive and power saving and makes the production process speedy.

We provide the range of fully automatic plastic injection moulding machines to our customers. We offer these products in global market within definite time and at affordable prices, with following specifications:

|

Make |

|

JSW |

|

Model |

|

JSW50ED |

|

Making Year |

|

1992 |

|

clamping force |

Ton |

50 |

|

screw diameter |

mm |

22 |

|

shot weight PS |

g |

56 |

|

shot volume |

cm |

1120 |

|

injection pressure |

kgf/1/2 |

1640 |

|

tie bar distance H x V |

mm |

310 x 310 |

|

mould height min |

mm |

180 |

|

mould opening stroke |

mm |

300 |

|

Total Opening ( Daylight) |

mm |

550 |

|

Ejector stroke |

mm |

125 |

|

Ejector Force |

Ton |

2.3 |

|

main motor |

Kw |

11 |

|

heating total Load |

Kw |

5.6 |

|

machine weight |

Ton |

4.4 |

|

dimensions of the machine L x W x H |

m |

3.95 x 1.84 x 1.92 |

|

Oil Tank |

|

300 |

Engineered for Precision and Efficiency

The JSW J50ELIII is crafted to deliver high-precision plastic mouldings with minimal waste. Its 50-ton clamping force, advanced hydraulic system, and four heating zones enable complex shapes and consistent output. Its Japanese engineering ensures durability, and the energy-efficient design leads to reduced operational costs for manufacturers across India and overseas.

Versatile and User-Friendly Operation

With easy-to-navigate controls and a broad mould accommodation range (150 mm360 mm height), the JSW J50ELIII simplifies setup and operation for experienced technicians and newcomers alike. Its spacious tie-bar gap and high shot volume support versatile production needs, making it an ideal choice for a variety of plastic products.

FAQs of JSW 50TON Injection Moulding Machine:

Q: What types of plastic products can the JSW J50ELIII Injection Moulding Machine manufacture?

A: This injection moulding machine is suitable for a wide range of plastic products, including small to medium-sized components used in automotive, electronics, packaging, and consumer goods. Its precision and high output make it adaptable to various industry applications.Q: How does the machine ensure high precision during the moulding process?

A: The JSW J50ELIII utilizes a 32 mm screw diameter for uniform plasticizing, combined with a powerful 1800 kg/cm injection pressure and advanced four-zone heating. These features work together to deliver consistent material flow and precise component dimensions.Q: What are the key energy-efficient features of this model?

A: This model incorporates an 11 kW pump motor and optimized hydraulic circuitry to reduce energy consumption without compromising moulding performance. Its design supports decreased operational costs while maintaining high productivity.Q: When is regular maintenance recommended for this used machine?

A: Its advisable to perform regular maintenance every 612 months, depending on usage intensity. Regular oil checks, filter replacements, and inspection of heating zones and tie bars help ensure sustained, reliable performance.Q: Where can I install the JSW J50ELIII, and what are its space requirements?

A: The machine is best suited for industrial manufacturing facilities with enough floor space to accommodate its dimensions: approximately 4.2 x 1.2 x 2.1 meters. Adequate power supply (380V, 3 phase) and access to cooling water are essential.Q: What is the process for setting up a mould on this machine?

A: Begin by adjusting the mould height between 150 mm and 360 mm, ensuring it fits within the 340 mm opening stroke and the tie bar spacing of 410 x 370 mm. Secure the mould, connect cooling water, check the oil levels, and program the heating zones according to material requirements before starting production.Q: What are the benefits of purchasing a 2016 used JSW J50ELIII in good condition?

A: Buying this well-maintained, used machine provides cost savings while still delivering robust performance and reliability. Its high precision, energy efficiency, and easy operation make it a valuable asset for both established and emerging plastic manufacturing businesses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Used Plastic Injection Moulding Machinery Category

Semi-Automatic JSW 450 Ton Used Injection Molding Machine

Condition : Used

Capacity : 450 Ton

Voltage : Not Provided

Feature : SemiAutomatic

Used For : Plastic molding applications

Color : Grey

Arburg 60Ton

Condition : Used / Second Hand

Capacity : 60 Ton Clamping Force

Voltage : 400 V

Feature : Fully Automatic, High Precision, Energy Efficient

Used For : Plastic Product Manufacturing

Color : Green

Nissei 40Ton

Condition : Used

Capacity : 40 Ton (Clamping Force)

Voltage : 220 V

Feature : High precision, stable operation, compact design

Used For : Plastic Injection Moulding

Color : White & Green

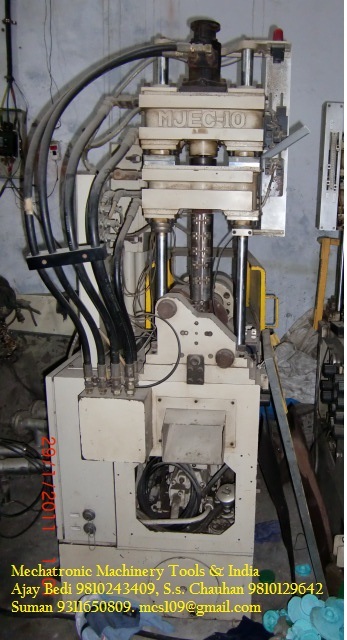

M Jec 10 ton make:-1997 L Type

Condition : Used

Capacity : 10 Ton

Voltage : 415 V

Feature : Sturdy construction, manual and automatic modes

Used For : Heavy material forming, bending, punching, straightening

Color : Sky Blue

|

MECHATRONICS MACHINERY & TOOLS (INDIA)

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry